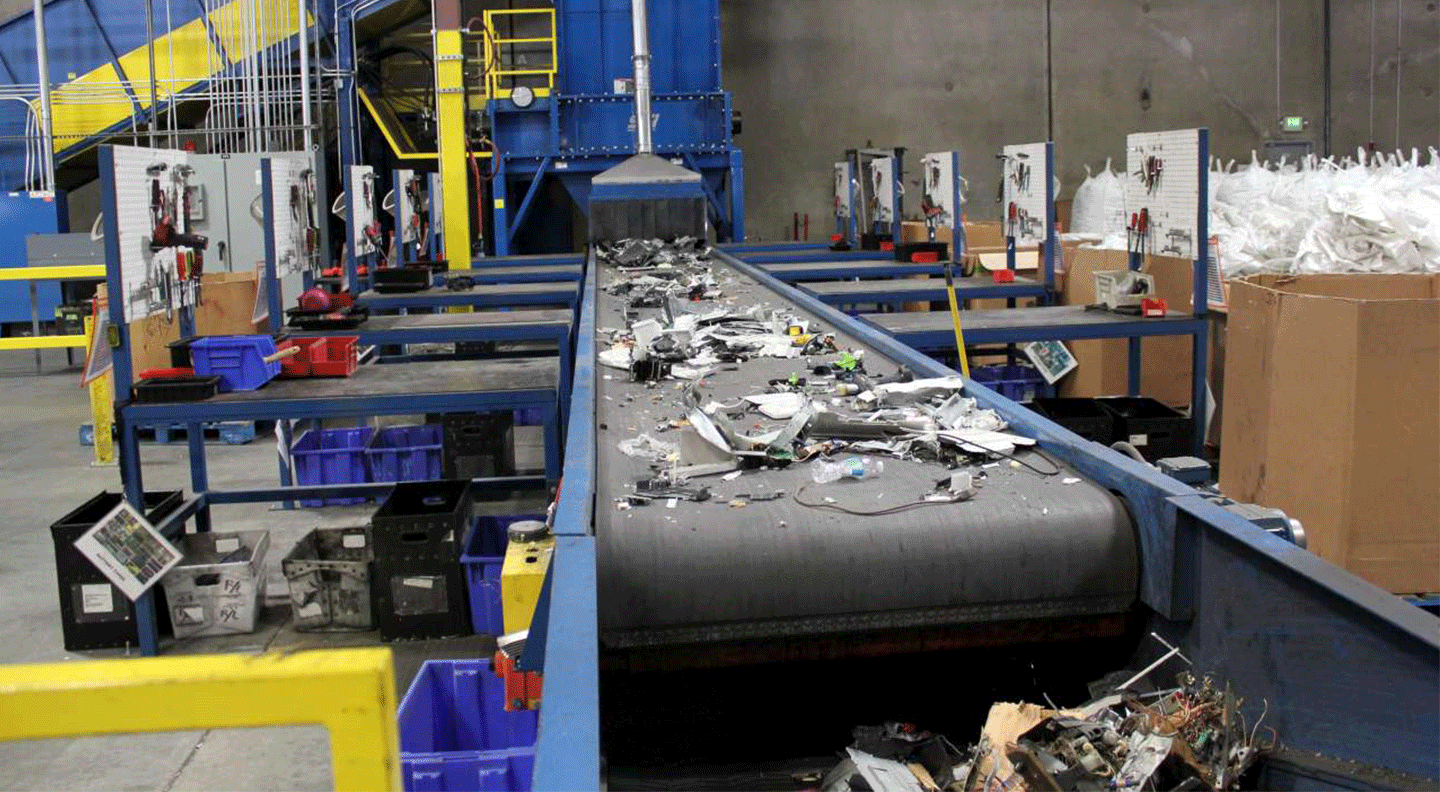

When recycling e-waste it is important to separate shredded materials into streams that are as clean as possible. These material fractions may include but are not limited to iron, aluminum, copper, plastics and printed circuit boards. Continuous evolution of the products being received at these electronics recycling and IT asset disposition (ITAD) facilities, forces operational adjustments. Without innovation these companies may lose opportunities to receive and process more equipment.

For example, Sims Recycling Solutions (SRS), a leading global provider of electronics recycling and IT asset disposition (ITAD) services, recently expanded their processing lines at the Eindhoven, Netherlands e-waste facility. This site, known to be the largest e-waste (WEEE) recycling operation in this region, added enhancements that include metals and plastics separation technologies. The newest innovation involves two new sorter lines which use metal sensors, color recognition and photo-technology to separate plastic, circuit boards and metals.

“Constant improvement in processing technologies is a high priority for SRS, as this enables us to securely deliver recycled and separated materials all over the world,” stated Marc Affüpper, director of SRS, EMEA. “By innovating our processing lines we are able to manage even the newest and complicated electronic gadgets.”

Operational enhancements, such as these, are not easy and provide a great deal of resources to implement. However these improvements contribute to a variety of benefits, some of which are listed below.

Supports Innovation.

The more open e-waste recyclers are to change, the easier it is for manufacturers to create new products. However it goes both ways because if ITAD companies never evolved they may not have the ability to process newer types of IT and electronic equipment being introduced to the market, so their services would remain limited to older legacy equipment.

Creates Efficiencies.

Automated processes make it easier for end-of-life electronics recyclers to efficiently separate and process the materials. If a task cannot be done mechanically, the job has to be performed using manual labor. If e-recyclers embrace newer technologies they could drive down costs, create cleaner streams and enable quicker processing of equipment.

Encourages Safety.

Usually when equipment is upgraded or enhanced it comes along with safety improvements. Reviewal of existing, as well as enhanced workspace will generally occur to ensure operational and employee safety. Features can also be added to minimize risks as well such as sensors that can detect fires, dust filters for air quality control, and improved equipment monitoring.

Improves Sustainability.

The goal at the end of the day is to reuse raw materials for as long as possible. Recyclers who can more effectively extract maximum value from resources, and recover materials from equipment helps transform more waste into reusable raw materials. Recycling diverts material from landfill or incineration and provides a feedstock for making next generation products, in support of the circular economy.

Encourages Collaboration.

If manufacturers and recyclers collaborated more we could reimagine the traditional materials economy model use of electronics to a closed-loop sustainable model. Recycler innovations could be a great motive to solicit discussions regarding management of electronic product lifecycles, reimagine supply chains, extend product design, and reuse and recycle products more efficiently.

Sims Recycling Solutions works with several major original equipment manufacturers (OEMs) to be more sustainable by supplying (circular-produced) recycled raw materials for their new products. These discussions are actually what helped drive new plastics sorting lines in Eindhoven that provide the option to process a dedicated batch of products as one single stream. This makes it possible to separate the plastics from a batch into a very clean stream of recycled plastics which can be returned to our OEM partners, creating a perfect triangle of circular material deliveries.

All these new developments contribute to a higher quality of recycled materials, provides the OEM electronics industry with new options toward sustainable product development, and contributes towards a more sustainable society.

Learn more about the circular economy.