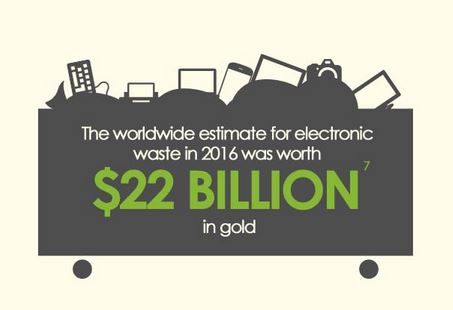

41.8 million tonnes (Mt) of electronic waste was generated in 2014, with a value of circa $52 billion, according to the United Nations. These types of material goods generate large amounts of physical waste, and their production can account for more than 80 percent of their through-life carbon footprint. The recycling and reuse of these materials can significantly impact our progression toward a carbon-neutral world.

Incorporating circular processes into the entire technology product life cycle will undoubtedly feature predominantly in our journey toward a zero-carbon sector. Many are working conscientiously to,

- Reduce waste,

- Reclaim raw materials,

- Increase reuse levels, and

- Incorporate the entire product life cycle into design conception.

Many are incorporating circular and zero-carbon initiatives into their operations, but only few are leading the way towards a truly net-zero carbon footprint. The best steps to ensuring your company is moving in this direction, are outlined below.

Define your goals: Write them down and share with your organization.

As many are aware, in 1979 a Harvard MBA course asked new graduates to set clear, written goals for their future and to make plans to accomplish them. Only three percent completed this. When interviewed 10 years later, the three percent who set goals were earning about ten times as much as the other 97 percent put together.

Measure your progress: Track against your goals accurately and regularly.

Measurements help shape behavior. They help maintain focus and allow for informed decision making. They also provide an opportunity to boast about achievements – increasing your profile, brand reputation and value.

Choose metrics which encourage the behavior you desire. Recent reports ranked European countries for their ‘circularity’ and environmental performance, and showed stark differences dependent on the measurements chosen.

Politico’s Circular Economy rankings favored Germany, the United Kingdom, France and Czechia by measuring against the goals of reducing waste, boosting recycling and encouraging reuse. The Nordic countries, generally acknowledged as environmental leaders, lagged behind. In contrast, the 2018 Environmental Performance Index, which ranks a broader range of environmental policies, sees Northern European countries leading the march.

If your goal is to achieve a zero-carbon product life cycle, ensure your measurements encourage appropriate actions.

Get started: Possible goals for the technology sector.

Weight – Create a goal for increasing the reuse of your technology assets, parts and components in addition to waste directed for recycling. You can consider measuring this by the amount (weight) of waste material diverted from the landfill.

Carbon – Set a goal to understand what is actually re-manufactured into new products by measuring carbon. Carbon has been identified as a better alternative measurement than weight in the report ‘Smarter Measures for the Circular Economy’. Others are also straying away from weight for this measurement, as the UK’s Environmental Services Association (ESA) is lobbying to not base new recycling targets on the current metric of weight.

When measuring carbon, measure more than just your own carbon footprint. Look at the complete supply chain and track the carbon profile for the entire life cycle of your assets. Search for suppliers with their own zero-carbon goals and clear strategies to reduce their environmental impact. Set targets for use of re-manufactured materials, and find efficiencies in your supply chain.

Asset Lifespan – Implement goals throughout the design life cycle of your equipment that could play a part in achieving a zero-carbon future. Align goals toward improving design for

- recycling,

- parts replacement or reuse, and

- use of re-manufactured materials over raw materials.

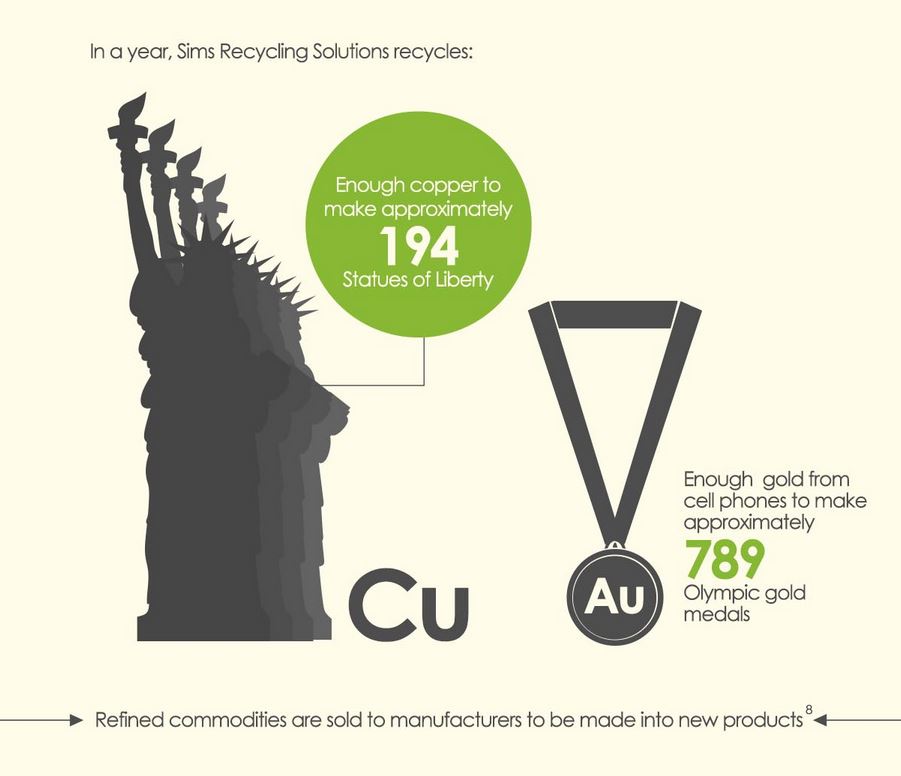

In an average year, the world’s leading recyclers will process:

Collaborate to achieve: Develop cooperation among all actors.

We can only achieve a zero-carbon future for the tech-industry if we work together. Engage all actors in your supply chain to collaboratively work on your goals to go beyond zero carbon and build restorative business models.

Learn how you can re-imagine your business model to strengthen current approaches and plan for continual evolution towards a circular model. Learn more