The superior performance characteristics of lithium-ion batteries enhance the performance of our electronic devices, as described in a previous blog post. However, the handling of lithium-ion (li-ion) batteries during the end-of-life phase of electronic products requires additional attention. If batteries are handled incorrectly, there is a higher risk of fire, pollution and other negative effects.

How do you recognize a lithium-ion battery? Every lithium-ion battery has li-ion as an identification mark on it. This can be inscribed in the material or placed on the battery as a sticker.

Are you a manufacturer, OEM or distributor of non-reusable electrical devices?

Here is a brief list of what you should and should not do with electronic devices that contain lithium-ion batteries. *Please note this article focuses on EU legislation and that different standards may apply in other regions.

Do

- Ensure batteries are removed from devices, and kept segregated, before further material recovery

- Approach a specialist to remove batteries if they cannot easily be separated and make sure the specialist processing facility has appropriate permits

- Insulate the battery terminals or wires to prevent short circuit

- Package batteries in UN-approved barrels or boxes (depending on type), separating layers with dry sand (for li-ion) or vermiculite (for other battery types)

- Follow the aforementioned UN-approved barrel process for damaged packages, and additionally package leaking or swollen batteries in plastic

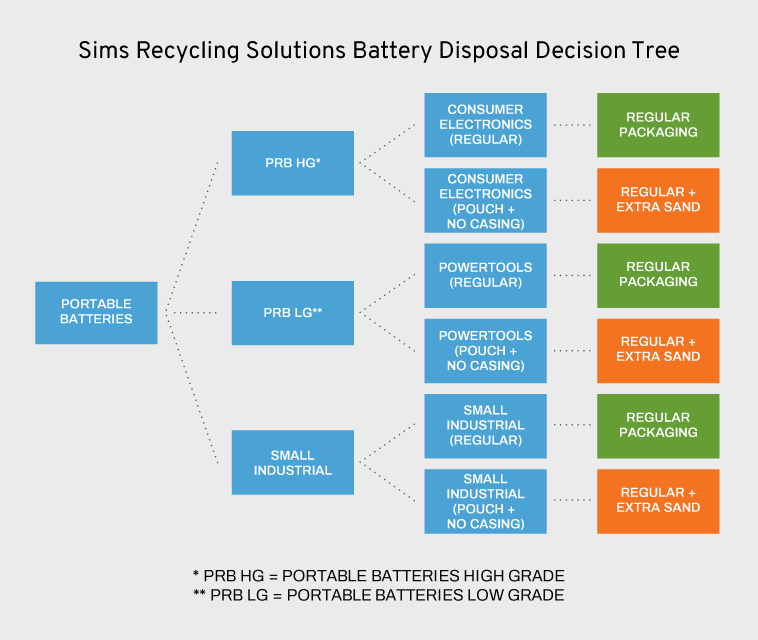

- Follow the Sims Lifecycle Services battery disposal decision tree at the end of this article

Don’t

- Dispose of li-ion batteries with ‘regular’ waste

- Crush, puncture, throw or do anything to the batteries that might result in electrodes touching and short-circuiting

- Mix damaged and non-damaged batteries

- Place large numbers of batteries together without proper segregation, as this presents an increased fire hazard

- Place batteries, or products containing batteries, in any process that is not specifically designed to accommodate batteries

- Store discarded li-ion batteries inside as these have a high risk of short-circuiting and catching fire.

Why can’t li-ion batteries be disposed of with normal chemical/industrial waste?

Lithium-ion (li-ion) batteries contain a variety of chemicals. Improper disposal has significant consequences, such as environmental pollution and loss of (material) resources.

Lithium is highly reactive and difficult to control. Influences such as high temperatures, too high charging voltage, short circuit, or even too much of a heavy strain can cause exothermic reaction – a chemical reaction that releases energy through light or heat – in the battery. In short: it can catch fire rapidly. This is why airlines cannot allow spare lithium metal batteries and lithium-ion batteries in checked baggage.

Li-ion batteries contain a thin sheet of polypropylene that separates electrodes and prevents short-circuiting. However, if a device is crushed or punctured, a thermal event can result, as batteries short-circuit when the separator between their positive and negative components are breached. The larger the battery, the stronger the thermal reaction. In this way, a discarded battery could ignite other flammable material adjacent to it. Especially if large numbers of batteries are collected, where just one lithium-ion battery might ignite.

Why is processing lithium-ion batteries as e-waste challenging?

There are three main reasons why processing li-ion batteries can be challenging. First, in many cases it can be difficult to remove these batteries from devices because they are bonded to the hardware.

The second reason: during the dismantling process, it can be very easy to damage the battery. For this reason, professional separation and recycling generally requires specialized tools, processes and controls.

Finally, due to high temperature exothermic reaction, several fire incidents can be attributed to lithium-ion batteries. High-capacity batteries can be discharged to reduce the risk of fire or the release of toxic fumes during processing. The likelihood of a thermal event needs to be classified considerably higher than for conventional batteries, including when batteries are in storage.

Different standards apply in different regions, such as Weeelabex and CENELEC, however waste batteries are covered by European regulation including the WEEE directive and the Batteries directive. Treatment facilities must have the correct permits in place for processing waste batteries.

How should consumers dispose of batteries?

Lithium-ion batteries can be recycled, but only at permitted treatment facilities. When discarded, they must be disposed of at a household e-waste collection point or battery-recycling drop off location. Of course, the electrical hazard needs to be carefully considered. High-capacity batteries can present an electric shock hazard as they can deliver higher voltages.

How should professional users / companies dispose of batteries?

Ensure lithium batteries are not exposed to high temperature or prolonged sunlight. Do not expose batteries to water or humidity. Handle these batteries carefully and package them so the safety device (casing) is not damaged. This can easily happen when batteries are stacked without a protective layer or placed beneath heavy objects. Also, ensure cores cannot come into direct contact with each other and make sure batteries are professionally discharged before further processing. Failure to do so can lead to batteries rupturing, catching fire or exploding.

Li-ion batteries contain materials that can be recycled with the right process. Recyclable materials include metal compounds, ferrous metal, aluminium, copper, graphite and plastic.

Sims Lifecycle Services has developed a battery disposal decision tree to help. This chart helps outline acceptance conditions and processing, and covers three different categories including (swollen) li-ion batteries, rechargeable (low-grade and high-grade) and small industrial batteries.

For safety reasons, batteries without protective casing and pouch cells have to be sorted separately for each of these three categories leading to six potential sorting categories (see diagram).

The Procedure at Sims Lifecycle Services

Undamaged batteries from electronic devices

Regular packing

Remove attached wires unless contacts are connected, which should be isolated using insulation tape. Undamaged batteries may not be covered in plastic bags or foil. Batteries should be placed in a UN-approved barrel (200L barrel or 400kg pallet box) with an inner plastic lining.

Place a 10 cm layer of dry sand (for lithium-ion) or vermiculite (for other battery types) at the bottom. Then a layer of batteries can be added to the barrel and be covered by a 10 cm layer of dry sand or vermiculite and so on.

Damaged, swollen or leaking batteries from electronic devices

Regular packing + plastic bag/foil and extra sand

Remove attached wires. Place battery in a clear plastic bag, or wrap in clear plastic foil. Batteries should be placed in a UN-approved 200L barrel with an inner plastic lining. Place a 10 cm layer of dry sand (for lithium-ion) or vermiculite (for other battery types) at the bottom. Then a layer of batteries can be added to the barrel and covered by a 10cm layer of dry sand or vermiculite and so on.

Do not mix damaged and non-damaged batteries. Each type must store in its own UN-approved barrel. Weight should be 1/3 sand and 2/3 batteries. Damaged, leaking or swollen batteries should be packed in plastic.

Devices with swollen batteries

Place device in clear plastic bag, or wrap it in clear plastic foil; then place products in a UN-approved 200L barrel with an inner plastic lining. Place a 10 cm layer of dry sand (for lithium-ion) or vermiculite (for other battery types) at the bottom. Then a layer of products can be added to the barrel and covered by a layer off 10cm dry sand or vermiculite and so on.

Do not mix damaged and non-damaged batteries. Each type must store in its own UN-approved barrel. Weight should be 1/3 sand and 2/3 batteries. Damaged, leaking or swollen batteries should be packed in plastic.

Batteries not allowed to be processed further

Battery scrap must not contain radioactive elements, products, or materials and cannot be attached to any other battery scrap or object including, without limitation, a plastic, steel or aluminum base (e.g. no complete laptop computers or other intact consumer electronics).

Each category as mentioned above (1, 2, and 3) should be packed in a separate UN-approved 200 litre barrel. Mixing of categories in one barrel is strictly forbidden. Each UN-approved barrel should be labelled with a sticker stating category 1, 2, or 3 and the following description:

- Cat. 1. Undamaged batteries, mentioning also: ‘Lithium-Ion’ or ‘other battery types’

- Cat. 2. Damaged, swollen or leaking batteries, mentioning also: ‘Lithium-Ion’ or ‘other battery types’

- Cat. 3. Devices with swollen batteries, mentioning also: ‘Lithium-Ion’ or ‘other battery types’

Need More Information?

SLS supports safe and responsible electronics recycling. If you would like to outsource your dismantling, sorting and material recovery of devices and li-ion batteries, contact us today.