Insight into the Process at Sims Lifecycle Services

Project planning

Sims Lifecycle Services (SLS) has completed many edge decommissioning projects and is well prepared to manage the variable nature of edge work. We pre-plan on-site work, resourcefully problem solve, and adapt to unique site conditions.

Site preparation

We show up on site, ready to tackle decommissioning in a systematic and organized way. Decisions on how equipment will be tracked and inventory managed, are verified with the site manager. We coordinate with the site manager to ensure our work does not conflict with their on-site priorities. We evaluate the site and develop a safety plan to ensure work is done in a safe manner. Safety lanes are defined with safety cones to ensure adequate separation of people from vehicles and equipment.

Each day begins with a huddle board planning session to update and modify prepared project plans based on changing day-to-day site conditions.

Decommissioning edge data centers

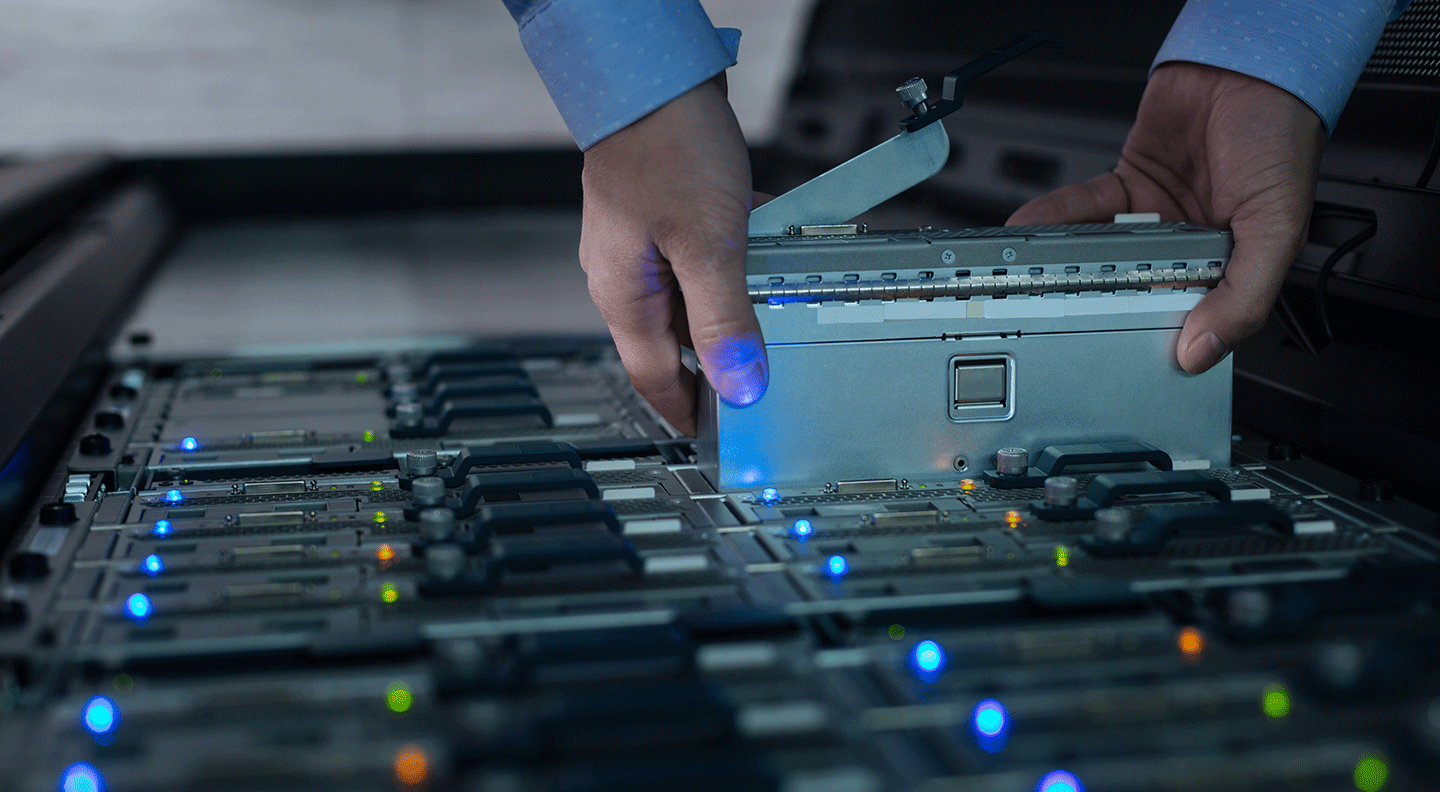

Staged decommissioning of equipment includes:

- Removal of cords and wiring

- Pulling blades, servers, hard drives and power supplies

- Separating battery packs from servers so they can be packaged individually for safe shipping

- Removal of network switches from racks

- Stacking equipment on pallets and in pallet boxes, and wrapping and labelling of palletized equipment

- Loading pallets and pallet boxes on a truck for shipping to a SLS processing facility

REMOVAL OF ELECTRICAL AND MECHANICAL SYSTEMS

Did you know? Sims Lifecycle Services manages reuse and recycling of retired IT equipment. Our Sims Metal Management division recycles metal equipment including generators, UPS, PDU, and cooling and air handler equipment.

Preparing IT equipment for shipping

We typically pack about 100 blades and servers per pallet, stacking five servers per layer, with 20 layers per pallet. Pallets are shrink wrapped, banded and labeled.

Ensuring chain of custody

Once pallets and pallet boxes are loaded on the truck, SLS personnel takes pictures of the load and the truck seal, prior to sealing the truck. The truck driver signs off on paperwork and the equipment is shipped to a SLS processing facility.

Receiving and check-in at SLS facility

Shipping paperwork, the intact seal and the seal number is verified with the truck driver. Once the container is open, pictures are taken of the palletized equipment. All shipping paperwork is scanned and the scanned documents become part of the electronic order confirming chain of custody.

Equipment is scanned into our inventory system for electronic tracking. Each asset is evaluated and prepared for whole unit resale, parts recovery or recycling. As a single source provider, SLS offers all of these services.

Data Destruction

SLS provides data destruction on site at the data center and at our SLS processing centers. All data is destroyed per NIST 800-88 r1standards. Hard drives are removed and erased if being resold. If resale is not an option, either because of client requirements or age of drive, the drives are rendered data safe through shredding.

Value recovery of data center equipment

Parts Recovery

Designated parts are recovered to be used as data center spare parts or resold on behalf of the data center.

Product Resale

Whole units with resale potential are prepared for resale. Parts are tested and cleaned and prepared for reuse or resale. Our pricing analytics tool helps us determine optimum pricing for selling used data center equipment.

Recycling

Broken and obsolete equipment is responsibly recycled. Our facilities are certified to industry standards. Certificates of Recycling provide proof and details of when and where equipment is recycled, and confirmation of environmental compliance.

Reporting

We provide several standard reports that provide chain of custody proof points that confirm equipment receipt, count and condition. Reports include make, model, serial number, date received, weight, and how and when the equipment was resold or recycled. SLS supports multiple currencies and additional data capture for clients with unique requirements.

Important Notes:

It is important that a disciplined and planned approach is taken when decommissioning equipment at the edge. If a data center is powered down and equipment sits in an uncontrolled environment, equipment can be unnecessarily damaged, resulting in lost resale/reuse opportunities.

SLS offers turnkey services for edge data centers that includes decommissioning and reselling IT, mechanical and electrical equipment.