Refurbished semiconductors come to the rescue of data center providers and OEMs

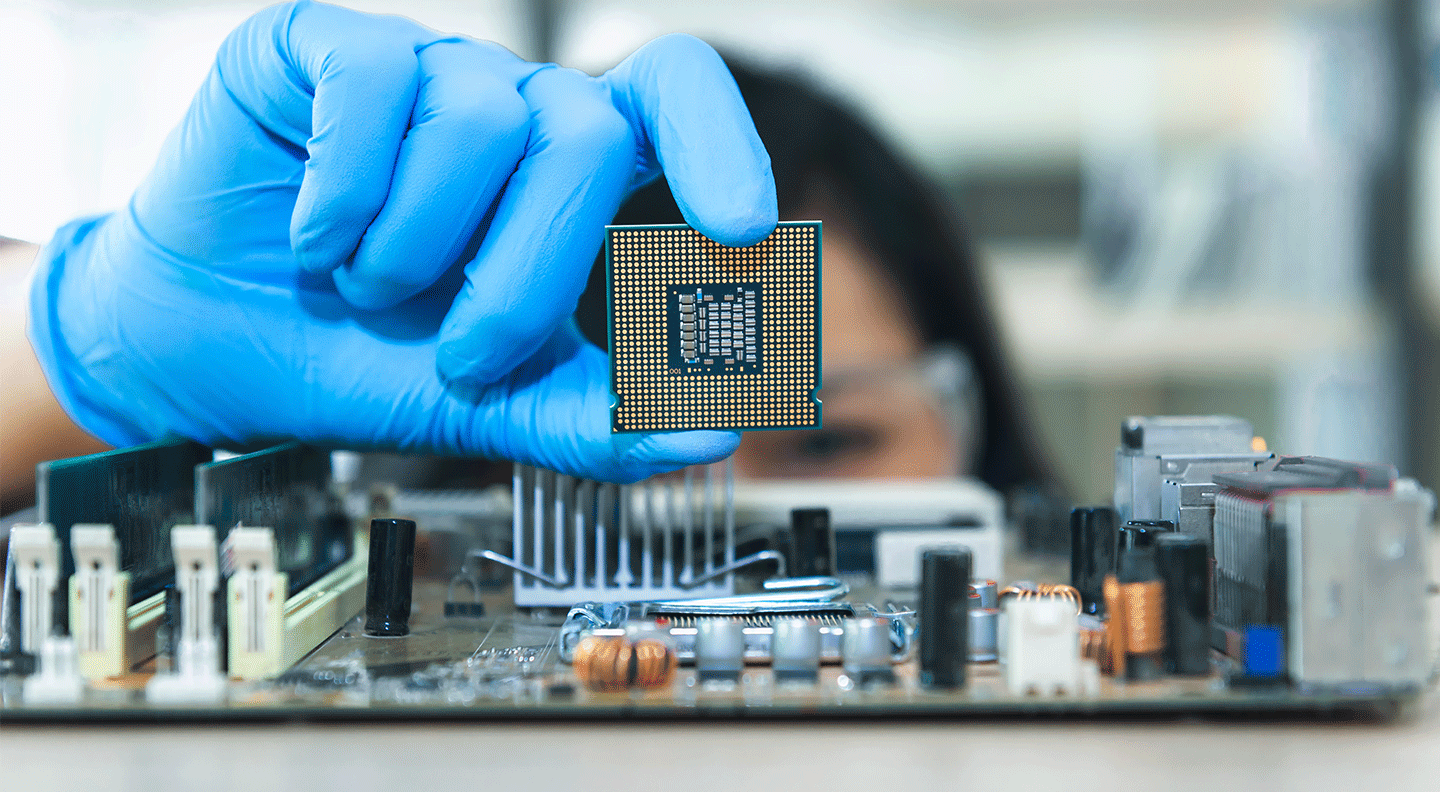

As we become more reliant on technology in our everyday lives, the demand for semiconductors is surging. These small chips power everything from digital devices to data centers, and today, they are in short supply across the globe due to COVID-19-related production and supply chain issues. To meet this demand, Sims Lifecyle Services (SLS) is helping customers to recover and redeploy their used semiconductors, along with other processors and memory. In addition to helping address supply chain woes, this reduces the carbon footprint and costs compared to producing and purchasing new equipment.

During the pandemic, everything from work and school to shopping became dependent on consumer electronics and collaboration platforms like Zoom and Microsoft Teams, which run in the cloud and require chips at data centers.

Companies from vehicle manufacturers to toy manufacturers decreased orders for electronic components, expecting decreases in their product sales. At the same time, the factories that produce semiconductors were forced to close for months. As a result, demand for refurbished semiconductors, processors and other memory equipment has doubled since the COVID-19 pandemic.

SLS’ expertise in IT asset recovery facilitates more strategic discussions with original equipment manufacturers (OEMs) on how to manage reverse logistics and recover value from returned equipment. Recovered components are used as spares for existing machines or sold in secondary markets.

Sean Magann, chief commercial officer of SLS, is excited to see the industry further embracing refurbished equipment. He says, “As components become harder to find, our IT OEMs are realizing it is possible to reverse engineer and recover semiconductor chips from end-of-life equipment. They want all the memory back. Even our customers who run big data centers, where most equipment is proprietary, see that there are circuit boards with generic chips that can be recovered and put back into the supply chain.”

Redeploying assets in other applications maximizes value return while also fits into wider corporate sustainability strategies, Magann says. “It’s heavily driven by sustainability efforts to track and reduce everybody’s carbon footprint. These are highly engineered products with significant material and manufacturing footprints, since one memory drive can be responsible for more than 0.5 kg Co2e over its lifecycle.” 1

Once the shortage abates, Magann says that he believes more OEMs will continue to adopt a circular approach as they realize the benefits to their business and the supply chain. “Extending product, part and material lifecycles also enables financially and environmentally sustainable circular electronic supply chains,” he says. “It will improve the flexibility of supply chains that contributed to global shortages, expand capacity, and save carbon and materials that would have been used to produce new products.”

Learn more about how SLS’ redeployment services can extend the lifecycle of your IT equipment visit: https://www.simslifecycle.com/business/it-asset-recovery/

1 Boyd, S. B. (2014), Life-Cycle Assessment of Semiconductors, Springer, p. 94